Microscope objectives, also known as objective lenses, are probably the most identifiable pieces of the microscope. This is primarily because these are the pieces of the microscope that are the closest to the specimen or the “object”. This is where the name “Objective” comes from.

A Microscope objective is a bullet shaped apparatus that contains a series of compounding lenses which collect light and produce a magnified image on the image plane of the microscope. The objective lense in screwed into the revolving turret (nosepiece) which aligns and locks the objective into place for observation.

Objective Lens Overview

The objective lens can be characterized as the eyes of a microscope. The objective lens gathers light refracted through and around the specimen and then through a series of processes transforms, and magnifies the light image where it eventually reaches the observer. The objective lens is the most complex and most expensive part of the microscope in most cases because of the multi-element design and function.

Objective lenses play the largest role in image magnification, and can be a significant role in determining the overall image quality of the microscope. The objective is also the most challenging component in an optical microscope.

Major microscope manufacturers offer a wide range of objective designs with several unique applications and designs. Objective lenses vary widely in quality and design and can be roughly classified based on:

- Intended purpose

- Microscopy method

- Performance

- Magnification aberration correction

The objective lens has a front hemisphere lens and a second meniscus lens. They both work together to assist in capturing light rays at a high numerical aperture with minimal spherical aberration.

Many objectives also have a spring-loaded retractable nosecone assembly that protects the front lens form colliding with specimens.

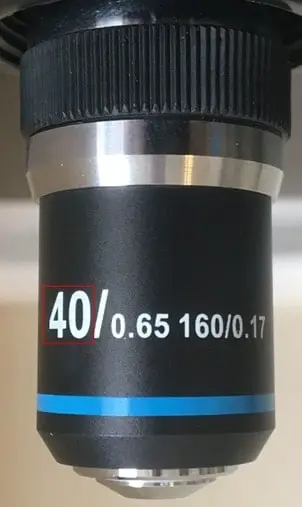

You can find the specifications on any given objective by looking at the objective barrel. Manufacturers imprint details such as numerical aperture, magnification, optical tube length, degree of aberration correction, and other vital information.

Objectives also use different mediums to transfer images from one lens to another. Mediums like air, water, glycerin or specialized hydrocarbon-based oils can be used as long as it has a higher refractive index. This will be covered later in the article when we discuss wet objectives.

Classification of Objective Lens by Microscopy Method

The difference in the microscopy method can play a significant role in determining the different types of objective lenses used.

Reflected dark surface: These have a particular construction of a 360-degree hollow chamber which surrounds the centrally located lens elements.

Difference interface contrast: This uses stain-free optical elements and depends on the action of the Nomarski or Wollaston prism. These prisms determine the visual path differences between shared light beams at the rear focal plane.

Fluorescence objectives: designed for high transmissions of light from ultraviolet to infrared regions by using quartz and unique glass.

Phase contrast objectives: these types of objectives are subdivided into several categories depending on neutral density and construction of the internal phase ring. For more on phase contrast microscopy see this post.

Classification of Objective Lens by Magnification

Objective lenses can be categorized by how much magnifying power they have. The magnification levels are also color coded to give a visual indicator of magnification level.

- 1 – 1.5X: Black

- 2 – 2.5X: Brown

- 4 – 5X: Red

- 10X: Yellow

- 16 – 20X: Green

- 25 – 32X: Turquoise

- 40 – 50X: Blue

- 60 – 63X: Blue

- 100 – 250X: White

Classification of Objective Lens by Aberration Correction

There are two main kinds of chromatic correction. Chromatic correction is the lens’s ability to focus all wavelengths on the same point. Achromatic objectives are the most straightforward, cheapest, and most common objectives. These objectives correct chromatic aberration in both red and blue wavelengths. They also correct spherical aberration on green wavelengths. Achromatic objective lenses are what ship with most microscopes especially lower end microscopes.

They are affordably priced and you can pick up different magnifications other than the standard 4X, 10X, 40X, 100X (oil) objectives on Amazon or any other microscope dealer. I bought this 60X objective lens to replace my 100X oil objective because I never use it and I would highly recommend it.

The main weakness of this types of objective it that it has a limited correction for chromatic aberration, and it lacks a flat field view. These lenses are also specialized for monochromatic applications.

Apochromatic objectives can also correct spherical aberrations for two and three wavelengths in addition to some numerical aperture and long working distance. Because of its well-designed structure, apochromatic objectives have an advantage during white light applications.

Apochromatic objectives are extremely expensive as you can see but if you have the money and you are really wanting to take you micrography to the next level they are well worth the investment. If I could ever convince talk my wife into it I definitely would!

Refractive and Reflective Objective Lenses

The refractive objectives lenses are the most common objectives used. This objective enables light bends to be refracted by an optical element. This element is designed in a manner that reduces back reflections, thereby improving the lighting of the specimen seen through the eyepiece.

These types of objectives are typically used in applications that demand resolution of the most excellent quality. The refractive objectives design ranges from two elements in its basic achromatic objectives to fifteen elements in plain apochromatic objectives.

Reflective objectives use reflective mirror-based design, as its name suggests. These objectives, although they may not be as common as refractive objectives, overcome certain design flaws in refractive objectives.

Objective Standards

Microscope objectives made to this standard are compatible with other microscopes made to the same standard and can be interchanged easily. The DIN standard has 160mm distance from the object slide to the eyepiece. The other standard, JIN, is the Japanese industrial standard, which has 170mm from the flange to the eyepiece.

You need to know the distance of your microscope has before choosing a scope to use. If chosen wrongly, you will end up looking at a skewed representation of your slide. Though both DIN and JIN are different in their lengths, they are the same in optical quality. Similarly, they both use the same RMS mounting tread of 0.7965″ x 36TPI.

Magnification

Both the eyepiece and the objectives magnify the object, which gives the magnified images you see when you look through most objectives also have a color band along its frame that indicates the level of magnification. Colors like green yellow and red are used to show intensity.

For example, a yellow band indicates 10x magnifications. For more on microscope magnification see Microscope Magnification: Explained.

Anatomy of an Objective Lens

Most of the objectives you’ll find today are composed of several glass lenses. These lenses are made for high quality and performance, with a given extent of correction for aberrations and flatness of field. These features are what determine the varying prices of objectives.

The materials used and the construction techniques of objectives has seen significant improvement over the past 100 years. Today, Computer-Aided Designs (CAD) systems and advanced rear element glass formulas are used. As a result, you get that crystal clear, uniform composition and quality lenses, each having a highly specific refractive index.

These advanced formulas help manufacturers produce objectives that are very low in dispersion and are designed for better corrections from most optical artifacts such as coma, geometrical distortion, and more.

Manufacturers have also drastically reduced the image flare and at the same time, improved light transmissions. As a result we have better images that are remarkably sharp, bright, and precise.

Achromatic Objectives

Achromatic objectives are the least expensive and most common type of objectives used. These objectives are corrected for axial chromatic aberration in only two wavelengths. Both blue and red wavelengths between 486 and 656 nanometers are corrected to the same focal point.

Achromatic objectives are corrected for spherical correction of 546 nanometers in color green. The limited correction in achromatic objectives can lead to important artifacts when objects are observed and imaged with a color microscope. If the color is chosen in the green spectrum, images typically have a residual color.

Achromatic objectives produce the best images when light passes through a green filter (oftentimes an interference filter). Black and white film are used when these objectives are used for photomicroscopy. These objectives lack field correction (flatness of field), which further limits achromatic objectives.

In recent years, manufacturers have improved the field corrections of achromats by introducing flatness correction lenses. These improved types of chromatic objectives are called plan achromats.

Achromatic Objective Overview:

- Spherical aberration: 1 color

- Chromatic aberration: 2 colors

- Field curvature: No

Fluorite Objectives

Fluorite objectives are also called semi-apochromatic. They have a higher level of correction and cost more than achromatic lenses. It is named after the mineral fluorite, which was originally used in their construction. Fluorite objectives have an additional spherical correction lens. Although it is quite similar to apochromatic objectives, the lenses used differ in thickness, curvature, and in its arrangement.

Fluorite Objective Overview:

- Spherical aberration 3-4 colors

- Chromatic aberration: 2-4 colors

- Field curvature: Yes

Apochromatic Objectives

Apochromatic objectives are the most highly corrected microscope objectives in the market today, and their prices reflect the sophisticated design and delicate assembly put into the manufacturing process.

Traditionally, apochromatic lenses are corrected for three colors red, green, and blue. This almost eliminates chromatic aberration and is corrected spherically for either two or three wavelengths.

Apochromatic is the best pick for color photomicrography in white light. Because of its high correction level, apochromatic usually have, for any given magnification, a higher level of numerical aperture than the achromats and fluorites.

Apochromatic Objective Overview:

- Spherical aberration: 3-4 colors

- Chromatic aberration: 4-5 colors

- Field curvature: Yes

Note: all three types of objectives suffer from pronounced field curvature and produce curved images instead of flat ones. They also have artifacts that increase in its severity with higher magnification.

To get flat images and overcome this limitation of curved lens surfaces, optical designers have produced flat field correction objectives. When added, they yield images that have common focus all through the field of view.

Objectives that use flat field corrections and low distortions have plan-added to the original lens type. This is why you may come across lenses named plan-achromats, plan-fluorites, or plan-apochromatic. Such correction objectives are quite expensive but are also very valuable in digital imaging and conventional photomicrography.

Uncorrected field curvature has been a significant problem for apochromatic and fluorite objectives, although it could be previously managed. During use, the view field would have been needed to focus at the center and the edges continually to get every detail of the image displayed.

But with the introduction of flat surface correction, corrections to the curvature of objectives are now near perfect for both general and high performing objectives.

More lens elements are added to correct field curvature compared to uncorrected objectives. A plan corrected objective can have as many as six additional lenses put together in more complex objectives grouping, which increases the optical complexity of the objective.

In the end, you get tightly fitted lens elements in fluorite and apochromatic objectives. In general, using a plan correcting an objective lens sacrifices a considerable amount of working space. You may find it a bit difficult to clean and maintain high magnification objectives which have a concave front lens.

What are Wet and Dry Objectives

Wet and dry objectives are named after the medium they use to transfer and refract light. The imaging medium between the front lens and the specimen cover slip affects the images produced for the correction for spherical aberration and coma in the design of each lens element for the objective.

Lower powered objectives, have a relatively low numerical aperture and are designed to be used with only air as its medium. It is the use of this medium that has given it the name “dry” objective.

Dry Objectives

These are objectives that use only air in between the objective front lens and the specimen cover glass and are not meant to be immersed in specialized immersion oils or liquids.

The maximum theoretical numerical aperture obtainable with air as a medium is 1.0. However, in practice, it is very difficult to produce a numerical aperture of up to 0.95 with a dry objective.

The cover glass thickness effect is negligible in dry objectives, which have a numerical aperture of less than 0.4. But such variations begin to matter when the numerical aperture reaches 0.65 where fluctuations as little as 0.1 millimeters can introduce spherical aberration.

This poses a problem for high power apochromatic objectives, which need a very short working distance in the air. It also contains a sensitive correction for spherical aberration, which tends to make it difficult to get sharp images.

To correct this, many high performing apochromatic dry objectives are fitted with correction collars. These collars allow adjustment to correct spherical aberration by correcting the variations in cover glass thickness. Optical correction is attained by rotating the collars which moves two of the lens element groups in the objective to move either closer or further apart from each other.

Wet Objective

Wet objectives also known as immersion objectives use liquids as a medium and are often the highest magnification objectives. This has the effect of significantly improving the numerical aperture. By using an immersion medium with a similar refractive index to that of the cover slip, poor image formation is practically eliminated. For more on immersion oil see this post.

Image deterioration is significantly reduced where light rays of wide obliquity no longer undergo refraction and are better grasped by the objectives. Immersion oils typically have a refraction index of 1.51 and dispersion similar to that of the glass coverslip.

Light rays that pass through the specimen and then through another substance of uniform thickness between the coverslip and the immersion oil. These light rays aren’t refracted as they enter but get refracted as they leave its upper surface.

It follows that if an object is placed at a focal point and in the center of the field of the objective lens, imaging by this portion of the lens system, is completely free of spherical aberration. The usual design of using an immersion oil lens is a hemispheric front lens element, followed by a positive meniscus lens and a doublet lens group.

Properly designed wet (immersion) objective lenses also correct for the chromatic defect, which is introduced by the first two lens elements. While doing this, it also minimizes the amount of spherical aberration. Light cones are also partially converged right before entering the first lens element which helps spherical aberration.

Note: Using immersion oil objectives without applying oil between the coverslip and the first lens element will result in a defected image.

This is as a result of the initial refraction that occurs at the surface of the front lens. It then introduces spherical aberration that cannot be corrected by other lenses within the objective.

The advantage of oil immersion objectives will be compromised if the wrong type of immersive is used. Microscope manufacturers produce objectives with a strict tolerance to refractive index and dispersion. Because of this, there needs to be a matching index in the liquid placed between the cover glass and the objective front lens.

It is advisable to use only the liquid suggested by the manufacturer and not to use different oils to avoid unpleasant artifacts. However if you do not want to mess around with oil objectives there are high magnification dry objectives that can be a substitute for an oil immersion objective. These high magnification dry objectives save the time and energy required to perform the oil immersion process and cleanup afterward.

Working Distance

Working distance is the margin between the front lens of the objective and the highest point of the specimen cover slip. In general, working distance reduces when numerical aperture increases.

The working distance between wet and dry objectives is also different. Dry objectives are created with the maximum working length possible while immersion objectives are limited on its working distance.

How do Objectives Determine the Resolution?

Resolution in Microscopes is used to refer to the ability of microscopes to distinguish details. An image forming light waves passes through the slide on display and move through the objective in an inverted cone.

The resolution of a microscope is linked to its numerical aperture (NA) of the optical component and the type of light used in examining the object. The resolution of a microscope hinges on the ability of the objective to gather the refracted light.

For more on resolution see What is Microscope Resolution?

For more on magnification see Microscope Magnification: Explained.

History

The creation of the first objective lens was credited to Galileo Galilei (1564 AD – 1642 AD) who had originally created it for use as a telescope but figured out that if they were rearranged could be used to magnify small objects. Although Galileo is credited with the creation of the first objective lens there were discoveries of glass lens artifacts dating back to the Assyrian civilization in 710 B.C.

The next major development in objectives design occurred when Hans Boegehold constructed the first plan achromat and plan-apochromat objectives in the 1930s.

More recent developments of chrome-free optics by Zenji Wahimoto and Horst Riesenberg has led to a new revolution in microscope objective design. For more on the history of microscopes see The First Microscope to Modern Microscopes.

Takeaways

Microscope objectives are an extremely complex component of the overall microscope system. They have been refined and redesigned to give us some amazingly sharp and clear images at extraordinary magnifications. If a window on a house is a portal to the visible world, then the objective lens truly is a portal to invisible microscopic world.

References

- https://www.edmundoptics.com/knowledge-center/application-notes/microscopy/understanding-microscopes-and-objectives/

- https://www.olympus-lifescience.com/en/microscope-resource/primer/anatomy/objectives/

- http://zeiss-campus.magnet.fsu.edu/articles/basics/objectives.html

- https://www.rp-photonics.com/microscope_objectives.html